|

Here you will

find resources that can help further your lean transformation.

These resources are key to maintaining your continuous improvement

initiatives and can aid in the process of communicating your

shared vision for lean.

| ManagementWisdom.com |

| ManagmentWisdom.com is

a group of individuals—journalists, producers,

writers, and students of management—whose attention

was captured years ago by the profound implications

of the ideas of W. Edwards Deming and other pioneers

in systems thinking and its application to management.

Specifically they have a library

of videos about W. Edwards Deming.

Visit them on the web at: http://www.managementwisdom.com/ |

| JMAC:

Japanese Management Association Consultants |

| The Japanese

Management Association was created in 1942 with the

Consulting division at its core. In 1945 Shigeo Shingo

entered the service of the JMA, where from 1945 to 1959

he developed the tools of SMED, kanban, standardized

work, flow, and the elimination of non-value added activites

or waste. He cemented himself as a founder of continuous

improvement. JMAC was a driving force in the dissemination

of Deming's ideas both inside Japan as well as in many

other countries, and it originated hundreds of Kaizen

and Lean Manufacturing tools to assist Japanese companies

in the improvement of productivity and quality. The

main purpose of JMAC is to provide management consulting

services to promote organizational effectiveness specializing

in application and implementation. JMAC focuses

on planning, problem solving, systems analysis, training

and integrity. JMAC now enjoys the distinction of being

Japan's oldest, largest, and most prestigious management

consulting firm.

For more information about the JMAC visit them on the

web at:

http://www.jmac-america.com/ |

| Suggestion

Program |

| One of the

keys to sustaining continuous improvement is empowering

your workforce to implement lean practices. The Suggestion

Program is a powerful tool not only to encourage your

workforce towards continuous improvement, but also track

and monitor continuous improvement suggestions within

your organization as a best practice tool. The suggestion

program has the ability to store suggestions per employee

and assign reward points to those employees based upon

your continuous improvement reward system. The Suggestion

Program also has the ability to search all the suggestions

entered into the system in multiple ways. For more information

or to request a demonstration contact

us.

Click here for screenshots of the Suggestion Program

|

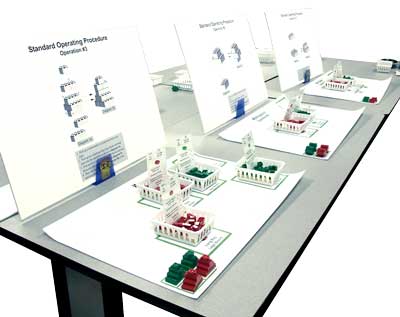

| Lean

Systems Simulation |

| The Lean Systems

Simulation is a tool used to compare and contrast traditional

manufacturing, or push systems, to lean manufacturing

or pull systems. Two complete production setups are

simulated using LEGO™ building blocks as raw material.

Participants receive a hands-on experience in simulating

a lean manufacturing processes utilizing Kanban, visual

management, andon's, and pull production methodologies.

A unique feature to our simulation is the addition of

key measureables and financial impact on each different

production phase. The Lean Systems Simulation is available

as a prebuilt kit for training at your facility, and

includes an instruction booklet for your trainers. For

more information about the Lean Systems Simulation,

contact us.

|

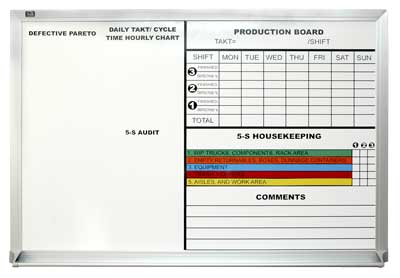

| 5S

Whiteboards |

| 5S whiteboards

help your organization report on their continuous improvement

efforts right on the production floor. These sturdy,

aluminum framed dry-erase whiteboards come pre-lettered

with areas for defective pareto, takt/cycle time charts,

5S audits, production tracking, housekeeping and comments.

For more information or to order a 5S whiteboard, contact

us.

|

| Lean

Assessment |

|

|

The Lean Systems

assessment is a 2-3 day process performed by Dennis

Doren, President - Lean Systems and Atsushi Terada,

President - JMAC. This fact finding survey will provide

an understanding of the correct metrics, review of flow,

and overall systems analysis. In addition to the entire

systems analysis, one specific process will be mapped

for value and a diagnosis will be provided. A final

report including a gap analysis and implementation plan

will also be provided. In addition, this benchmark survey

will be taught to your organization to use as a tool

for improvement efforts for the future. The following

ten categories will be assessed:

- Management/Cultural Awareness

- Quality, Problem Solving, and Customer/Supplier

Assessment

- HR, Training and Development

- 5S, Workplace Organization, and Visual Management

- Standardized Work

- Flexible Operations and Level Production

- SMED

- Total Productive Maintenance

- Material Control, Pull System, and Value Stream

Mapping

- Inventory and Lot Sizes

This tool can be used year after year by your internal

lean champions to gauge lean improvement efforts. |

| TAKT/Cycle

Time Data Sheet |

| This flexible

TAKT/Cycle Time data sheet will allow for hourly monitoring

of standard operations in each area of production. This

sheet will compare standard operation Cycle Time to

TAKT/customer demand expectations for proper resourcing,

visual management, and problem solving. This is a very

powerful tool for supervision and material control throughout

the value-stream to assist in flow and pull. This tool

can be updated daily for different customer demand,

mix, volume, days of inventory needed and/or shifts

ran. |

| Time

Study Boards |

|

|

Making decisions

using accurate data about production is vital in order

to progress on the journey of continuous improvement.

Time studies are an invaluable tool in gathering this

accurate data, and to be efficient at the collection

of time study data is key. These time study boards are

made of high durability plastic and have dual heavy-duty

stop watches attached to complete overall time and between

time studies. Below is a link where your company can

acquire the same high quality time study boards we recommend.

Meylan

Corporation Time Study Boards

(Note: Model No. 235 has dual stop watch holders.)

Meylan

Corporation Stopwatches

(Note: Model No. 224 is recommended.) |

| Time

Study Sheet |

| Use this time

study template to complete all of your time study needs!

Available as a FREE download from Lean

Systems Inc., you can print and copy this Adobe PDF

document as many times as you need. Click below to download

the time study template.

Time

Study Template (32 KB PDF  ) )

If you do

not have the Adobe PDF reader you can download it by

clicking on the Get Adobe Reader icon below.

|

| Vorne

Industries Inc. |

| Vorne Industries

Inc. is a manufacturer of TPM tools, specifically OEE

products, that maintain capacity/efficiency information,

downtime loss information, performance and quality loss

information. The three main statistical categories are

availability, performance, and quality. These innovative

products help you track realtime information, if you

aren't measuring its hard to improve. These products

and an example of a calculation sheet can be viewed

at the links below.

Visit their OEE page on the web at: http://www.vorne.com/solutions/learning_center/oee.htm

Also visit Vorne Industries OEE Calculation page on

the web at:

http://www.oee.com/calculating_oee.html

|

| Visual

Workplace LLC |

| Many of our

current customers are very satisfied with Visual Workplace

LLC. They offer in-house resourcing for your customized

visual management needs. This is done by developing

your own sign shop using hardware, software, and raw

materials recommended by Visual Workplace.

Visit Visual Wokplace LLC. on the web at:

http://www.visual-work-place.com/

|

|